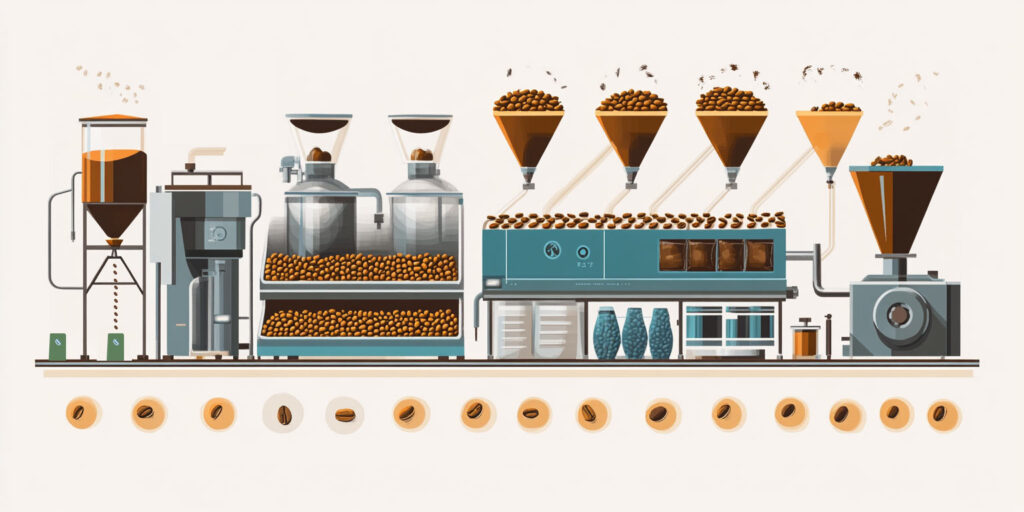

Coffee packaging machines work by combining automation and precision to seal coffee products securely. Here’s a simplified breakdown of the process:

- Filling: Coffee beans or grounds are measured and dispensed into packaging units, ensuring consistent amounts in every bag.

- Sealing: Using heat or pressure, the machine seals the package to lock in freshness and flavor.

- Labeling: Some machines also attach labels or print details like roast dates and lot numbers directly onto the package.

- Quality Check: Advanced models often include sensors to detect errors, ensuring every package meets quality standards.

These steps ensure that your coffee is delivered in pristine condition, ready to brew when it reaches you.

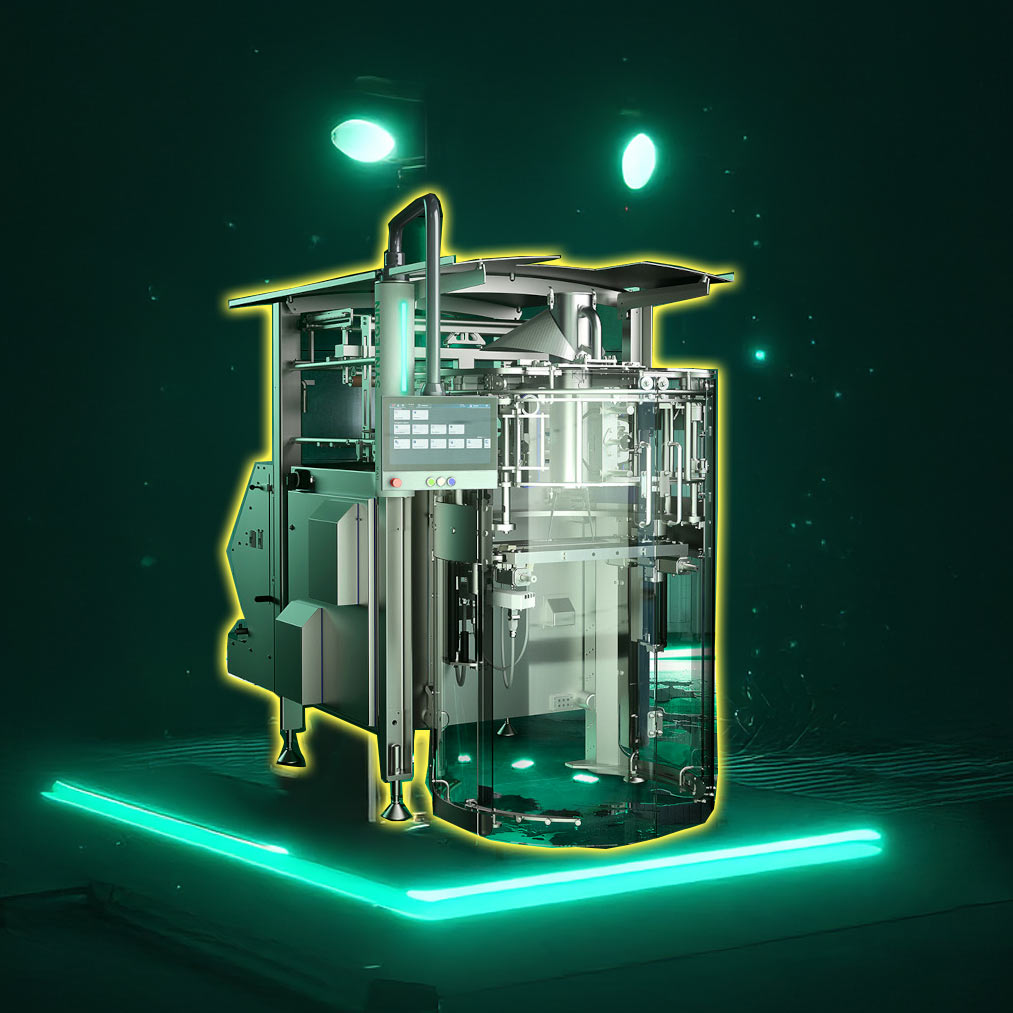

The Best Coffee Packaging Machines on the Market

If you’re searching for top-rated coffee packaging machines, these models stand out:

- Syntegon SVE Series: Known for versatility, this machine accommodates various packaging formats and sizes.

- ILAPAK Vegatronic: An industry favorite for speed and precision.

- Vertical Form Fill Seal Machines (VFFS): Popular for their ability to handle different coffee types, from whole beans to fine grounds.

Each machine offers unique features, so selecting the right one depends on your business needs and budget.

How Much Do Coffee Packaging Machines Cost?

The price of a coffee packaging machine can vary widely depending on its capabilities. Here’s a general idea:

- Entry-Level Machines: $10,000–$30,000. Ideal for small businesses with lower output needs.

- Mid-Range Models: $30,000–$100,000. These machines strike a balance between speed and features.

- High-End Equipment: $100,000 and up. Designed for large-scale operations with advanced functionality like automated quality checks.

Investing in the right machine is crucial for balancing cost with productivity.

Materials Used in Coffee Packaging Machines

Durability and hygiene are critical in coffee packaging. These machines are typically made from:

- Stainless Steel: Resists corrosion and maintains hygiene, perfect for food-grade equipment.

- Plastic Components: Used for specific non-contact parts to reduce costs and weight.

- Aluminum: Lightweight and corrosion-resistant for structural elements.

These materials ensure the machines can withstand the demands of coffee packaging while adhering to food safety standards.

Are Coffee Packaging Machines Eco-Friendly?

Sustainability is a growing concern in the coffee industry. Many coffee packaging machines are designed with waste reduction in mind, but some unavoidable waste does occur. Here’s how waste is managed:

- Material Optimization: Machines minimize excess material during the cutting and sealing process.

- Recyclable Packaging: Manufacturers often use recyclable or biodegradable films.

- Waste Recovery Systems: Advanced models include systems to collect and reuse leftover materials.

By choosing the right packaging options and technology, businesses can significantly reduce their environmental impact.

From Beans to Bags, the Future of Coffee Packaging Awaits

Coffee packaging machines are essential for preserving the quality of your brew while meeting modern efficiency and sustainability standards. As technology evolves, these machines continue to refine the process, ensuring your morning cup of coffee is as fresh and flavorful as possible. Whether you’re a coffee entrepreneur or simply a curious coffee lover, understanding these machines brings a new appreciation for the journey from bean to bag.